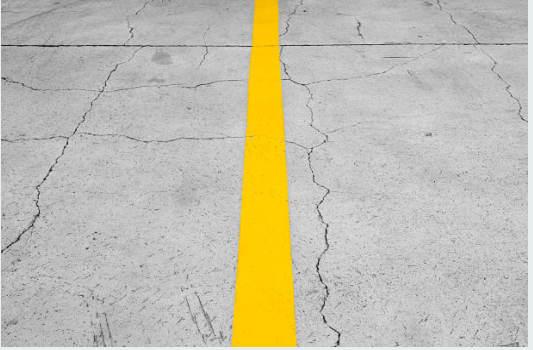

A brand new warehouse floor and its starting to fail. It doesn’t have to happen, and it can be prevented.

It’s common for concrete to develop cracks, scaling, crazing and pitting. All concrete has the tendency to crack, and it’s not possible to guarantee completely crack-free concrete however it can be controlled and greatly reduced.

Concrete expands and shrinks with changes in moisture and temperature. The overall tendency is to shrink, and this can cause cracking at an early age of the concrete. Irregular cracks are unsightly and difficult to maintain but generally don’t affect the integrity of concrete. While there is rarely a singular cause for a floor to crack badly it can often be put down to poor slab design.

The way a slab is designed is one of the most important consideration the decision makers needs to consider. When designed and installed correctly, concrete is one of the most durable and long-lasting surfaces you can get. But it is important that all parties involved in the design and the delivery of a finished concrete slab follow well-established guidelines with respect to concrete placement and curing. Durable, high strength, and crack resistant concrete does not happen by accident it’s a combination of design, sub-base conditions, concrete properties and placing techniques.

It has been well established that the inclusion of poly fibres, or cellulose fibres in concrete substantially contribute to reducing plastic shrinkage cracking. As an example of this, testing has proven that a poly monofilament fibre designed slab can reduce plastic shrinkage by up to 97%!

There are many types of fibre that can be used

- Structural Synthetic fibre (see Radforce)

- Wire crimped steel fibre (see Permaforce)

- Hook End steel fibre (see Hookend Fibres)

- Invisible cellulose fibres (see Ultrafiber500)

- Poly Strand Fibres (see Proforce)

- Poly Monofilament fibre (see Microforce)

All these fibres have different applications and properties. Their selection depends on the usage and environment of the finished slab. Consulting with a design engineer at iNFORCE to select the correct type of fibre to suit your particular application is recommended.

Wire mesh offers a two-dimensional, single layer reinforcement to a concrete slab, while fibre reinforces from top to bottom, providing a much stronger matrix of reinforcement than just a single level or dimension of reinforcement. Of particular note on this point, while mesh is mostly designed to sit centrally within the slab, the reality of that happening during the rigours of placing concrete is minimal unless particular care is taken. The care required is lessened substantially using fibre as the reinforcing is added and mixed under the quality control of the batching plant, reducing the risk of mis-placed reinforcement and weaker concrete as a result.

The tensile strength of reinforcing mesh come into effect only when they are bridging a macro or visible crack in the concrete matrix whereas short separate fibres provide a discontinuous, three-dimensional reinforcement that picks up transfers load stresses at micro-crack level. This type of reinforcement provides tensile capacity and crack control to the slab prior to the establishment of visible macro cracks, thereby encouraging higher ductility or toughness.

Get a trusted slab design from Inforce and simplify with confidence. With 20 plus years of experience in slab design, we can ensure you are left with a slab that is stronger, lasts longer and minimises the risk of cracking.

Written by Finn McGaveston